Head Pressure in HVAC is the pressure at the output end of an air conditioning system’s evaporator coil. The head pressure is affected by the temperature, humidity and airflow rate through the evaporator. Higher temperatures, higher humidities and lower airflow rates will all increase head pressure while cooler temperatures, lower humidities and higher flow rates will decrease it.

It’s important to keep head pressure within a certain range so that your air conditioner runs efficiently and doesn’t strain its components too much over time. Low pressures can cause condensation to form on pipes or other surfaces in contact with refrigerant causing damage to equipment or even leaking refrigerants if not corrected quickly enough.

Head pressure in HVAC systems is the resistance created by the refrigerant as it flows through the system. It can be measured at any point along the line and is used to determine how well an HVAC system is functioning. Head pressure affects how much cooling or heating output a unit produces, so it must be maintained properly for maximum efficiency.

High head pressures can cause wear and tear on components, reduce overall performance, and even lead to breakdowns if not addressed quickly. Proper maintenance of your system’s head pressure will help ensure optimal performance throughout its lifespan.

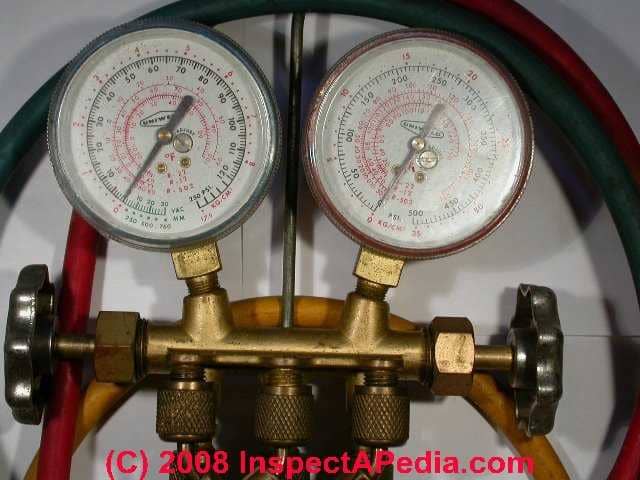

Credit: inspectapedia.com

What Determines Head Pressure in Hvac?

Head pressure in HVAC systems is determined by a variety of factors. Most notably, the amount of air flowing through the system and its resistance to flow can affect head pressure. If there is too much air flowing through the system, it can cause an increase in static pressure which results in higher head pressures.

This is why it’s important to balance airflow correctly when designing an HVAC system. Additionally, friction losses due to bends or turns within ducting will also contribute to increased head pressures. The type of fan used as well as their size and speed will determine how much static pressure they are able to produce at any given time.

Finally, changes in temperature or humidity levels can also affect head pressure since these elements impact the density of air within the system which affects static pressure readings taken with a manometer.

How Do I Check My Ac Head Pressure?

Checking your air conditioning (AC) head pressure is an important part of making sure it’s running efficiently. Head pressure refers to the amount of pressure in a system at any given time, and knowing what it should be can help you identify problems before they become more costly issues. The first step in checking your AC head pressure is to locate the discharge line.

This will usually run from the condenser unit, which is near where the compressor sits outside your home, up into the attic or interior of your home and should be easily identifiable due to its size. Once located, attach a gauge that measures psi (pounds per square inch) onto the end of this pipe by unscrewing one side and screwing on the gauge’s hose connector until tight. Turn on your AC unit with both inside and outside fans running, then read what is displayed on the gauge; this will tell you how much psig (pressure per square inch above atmospheric conditions) there currently is within your system.

An ideal reading for most systems would be around 250-350 psi when all components are functioning correctly—if yours reads higher than 400psi or lower than 200psi then contact a professional HVAC technician immediately as this could indicate certain parts need replaced or repaired in order to ensure efficient operation going forward.

What is the Head Pressure for 410A?

The head pressure for 410A is typically around 130-225 PSIG, depending on the application. In cooling applications, 410A has a higher head pressure than R22, which can make it more challenging to operate and maintain. However, its higher efficiency means that you will be able to get more heat out of every watt used when running an air conditioning system with 410A refrigerant.

When installing or servicing air conditioners using this type of refrigerant, it is important to ensure that your equipment is capable of supporting the increased head pressures associated with 410A before attempting any maintenance or repair work. Additionally, you should always use safety equipment and take all necessary precautions when working with high-pressure gases in order to avoid accidents or injury.

What is Head Pressure?

What is Head Pressure in Refrigeration

Head pressure in refrigeration is the difference between the suction pressure and discharge pressure of a compressor. It is an important factor to consider when designing a refrigeration system, as it affects efficiency and performance. The higher the head pressure, the harder the compressor has to work, resulting in increased energy consumption and reduced cooling capacity.

Head Pressure also plays an important role in ensuring that all components within a refrigeration system are operating safely and efficiently.

What is High Head Pressure for 410A

High head pressure for 410A is an indication of a system that has lost its ability to evaporate refrigerant correctly. This can be caused by many things including low charge, clogged air filters, restricted airflow, or dirty coils. High head pressure creates higher discharge temperatures and forces the compressor to work harder than necessary.

If you suspect your system is suffering from high head pressure for 410A, it’s best to contact a professional HVAC technician as soon as possible in order to prevent further damage and ensure optimal performance from your system.

How to Measure Head Pressure Hvac

Measuring head pressure in a HVAC system is important for proper operation. To measure the head pressure, you need to attach a digital manometer to the suction line of your system and take readings at different times throughout the day. The readings will tell you if your system is operating within its normal range or not.

You should also check the indoor temperature and humidity levels, as well as any air flow restrictions that could be affecting performance. With this information, you can make adjustments to ensure optimal efficiency from your HVAC system.

What Causes High Head Pressure in Refrigeration

High head pressure in a refrigeration system is typically caused by a low level of refrigerant, blockages in the evaporator coil, or dirty air filters. If there is insufficient flow of liquid refrigerant through the evaporator due to any of these issues, it results in higher than normal pressures within the compressor and other components leading to high head pressure. Regular maintenance such as cleaning condenser coils, checking for leaks and replacing air filters can help prevent this problem from occurring.

High Head Pressure, Normal Suction Pressure

High Head Pressure, Normal Suction Pressure is a common problem that can occur in an air conditioning system. It occurs when the compressor’s condensing unit has difficulty turning the refrigerant from gas to liquid because of high outside temperatures or inadequate airflow through the outdoor coil. This condition will cause abnormally high pressure on the discharge side of the compressor, while leaving suction pressure at normal levels.

To correct this issue, it is important to check for any blockages and obstructions in your ductwork, inspect your evaporator coils for dirt buildup, and make sure there are no restrictions in your lineset. If these measures do not solve the problem then it may be necessary to replace either parts or components of your HVAC system.

Low Head Pressure Hvac

Low head pressure in an HVAC system can be caused by a variety of different issues, such as low refrigerant levels, improper airflow, or dirty coils. If left unchecked, this can cause the system to not cool properly and run inefficiently. It is important to have your HVAC system inspected regularly to ensure that it is operating correctly and diagnose any potential problems before they become costly repairs.

What Causes Low Head Pressure

Low head pressure is caused by a variety of factors, including the size and shape of the container from which water is drawn, the rate at which water flows through those pipes, and even changes in temperature. It can also be caused by air bubbles trapped within the line or clogged filter screens. In some cases, low head pressure may indicate that there’s an obstruction in a pipe or valve somewhere along its path.

If left unchecked, this could lead to serious damage to your home’s plumbing system.

What Causes High Head Pressure 410A

410A is a type of refrigerant used in air conditioning systems and can cause high head pressure when there is an issue with the system. High head pressure can be caused by problems such as an overcharge or undercharge of refrigerant, restricted airflow, clogged condensate drains, incorrect fan speed settings, faulty expansion valves, and corroded components. It’s important to have your air conditioner checked regularly to prevent any issues that could lead to high head pressure.

Conclusion

Head pressure in HVAC systems is an important factor to be aware of. It can significantly impact the performance and efficiency of a system, and can even cause damage if left unchecked. Proper monitoring of head pressure and maintenance of an ideal operating range are essential for ensuring that all components continue to work properly as designed.

With careful attention given to this crucial part of the system, you’ll be able to enjoy a reliable, efficient heating or cooling experience for years to come.